In the recent past, the manufacturing industry for boats has gone through significant changes. High-end composite materials are in the process of replacing the conventional large-scale boat manufacturing methods that rely on wood and metal.

This industrial change generates modern benefits that transform boat building in Mallorca methods and deliver improved material qualities at reduced costs. The marine market evolves towards new heights because of composite boat manufacturing techniques, which now extend from luxury yacht building to superyacht construction and commercial ship development.

What is Composite Boat Building?

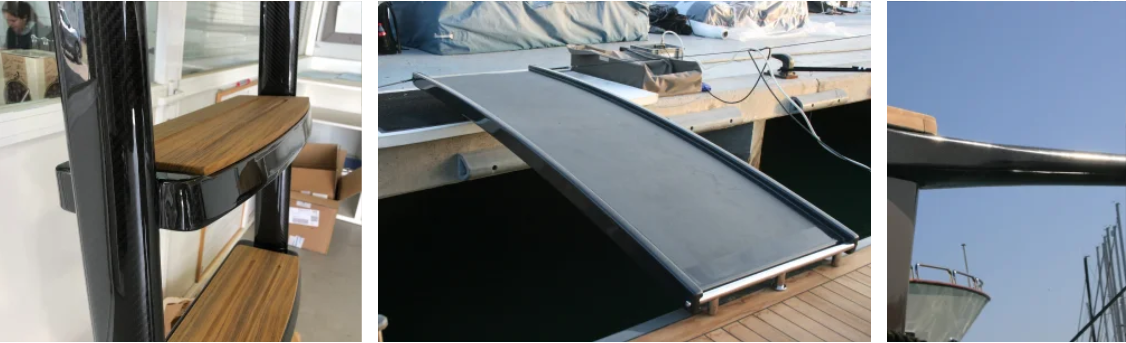

Boat manufacturers use modern synthetic materials, including fiberglass, together with carbon fiber, Kevlar and resin composites for constructing boats through composite boat building methods. These materials are lighter but remarkably more durable than wood or metal, so they provide numerous corresponding benefits.

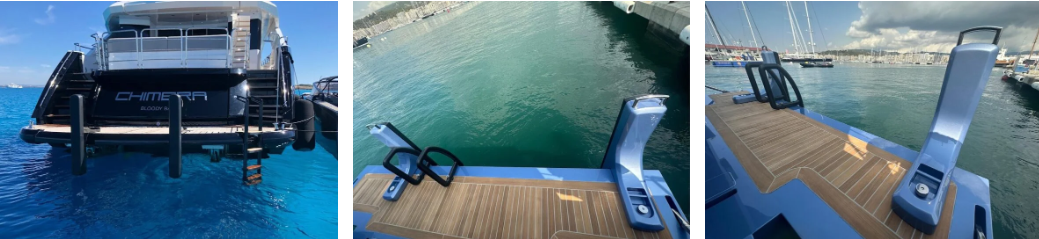

Strength and lightweight construction properties, together with high endurance, are specific requirements for boats that make composite materials an ideal fit for hulls, superstructures and decks. A typical boat manufacturing process starts when fibers are combined with resins before curing develops a stiff, resilient framework that remains lightweight. Weather and water do not impact the final boat structure, while its weight remains significantly lower than conventional boats.

Advantages of Composite Boat Construction

Light in Weight and High Strength

Among the several reasons composites have replaced metal and wood boat construction is that they possess a staggering strength-to-weight ratio. Composites are constructed of far lighter material than either aluminum or steel and, therefore, make faster boats with lower horsepower requirements and fuel needs. This manifests itself in running cost savings as well as increased performance, especially while racing and bluewater cruising.

Corrosion and Rot Resistance

Wooden or metallic boats, which are a norm of classic traditional boats, have the susceptibility of corrosion upon direct contact with seawater or from damage from the infestation by insects like termites. The composite will never rust and won't decay even in the worst possible environmental conditions, like exposure to seawater, ultraviolet sunlight, and hot and cold weather. That nature of the composite makes boats using composite as its material more reliable and reduces maintenance and high upkeep costs over repairs.

Durability and Longevity

Composites are built to withstand the hostile marine environment and, therefore, last many times longer than traditional boats. Whether under high-speed impact or continuous exposure to the elements, composite boats maintain structural integrity with no degradation of performance over time.

Design Flexibility

Composite materials provide improved design freedom than conventional materials such as wood and metal. Composites can be molded and shaped by builders with reduced difficulty into intricate shapes and streamlined designs that achieve both improved functionality and style. The styling freedom gained by using composites enables boat building Mallorca manufacturers to get creative, leading to bespoke designs that serve personalized needs and tastes.

Platform of Better Comfort and Better Insulation

Composite boats also have better thermal and acoustic insulation characteristics. The material employed dampens vibrations and noise, providing a more pleasant ride for passengers. Composite boats are also less prone to temperature changes, having the interior of the boat cooler in hot weather and warmer in cold weather.

In summary, composite boat building is not only the future of boat construction but also the secret to longer-lasting, high-performance, and environmentally friendly boats. If you're in the market for a luxury yacht, commercial vessel, or racing boat, composite material selection means a long-lasting investment and the ultimate boating experience.

Write a comment ...